Well planned

Those responsible for the project therefore made sure to use exceptionally resistant building materials. “This applied particularly to the floors in the laboratories and workshops,” explains architect Rainer Wild from Schwarz Architekten. “To make sure that we would use a floor covering that meets our criteria, we installed and tested different rubber and PVC floorings in trials conducted in a test container.” These test trials lasted nine months.

The acid test

The floor coverings were tested to establish whether they were abrasion-proof and resistant to chemicals. “Because many of the substances used in the laboratory are readily combustible, the electrical dissipation qualities of the floorings were also an especially vital factor,” says Wild. “A small spark can have catastrophic consequences.” To prevent accidents, the floor also needed to be slip-resistant. Another important aspect was easy cleaning.

A clear decision

“At the end of the test trials, the choice fell on floor coverings from nora systems,” reveals Thomas Volk, construction project manager at Bosch in the Facility Management Abstatt department. “Not only did they prove to be exceedingly robust and they fulfilled all our technical expectations, but they also fitted exceptionally well into the overall architectural concept. Colour-wise, they harmonise perfectly with the other materials such as the ashlar and needle felting.“ The fact that Bosch could rely on these coverings being available even years later for possible renovations and enlargements of the building also influenced the choice.

Safety with raised-access floors

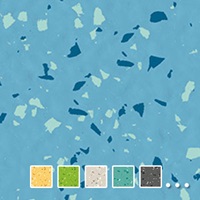

At the time, the designers of the development centre decided to use two different varieties of the rubber floor covering. “Due to the technical fittings, we had to be able to lay parts of the covering as a raised-access floors. This meant that coverings that were only available as sheetware were ruled out right from the beginning. A bonus point for nora systems,” explains Wild. norament 928 grano ed was therefore chosen for the technical areas because the rubber tiles are electrostatically dissipative, making them suitable for ESD-protected areas (EPA). They are also resistant to most acids and lyes. The building developers decided to use noraplan stone, which is installed in sheets, for the rooms where the floor does not come into contact with such substances. “The work didn’t present any problems,” explains Wild. “We just had to experiment with cutting to shape at the round supports.”

Denmark | English

Denmark | English