The material composition of nora® rubber surfaces makes them extremely resistant to chemicals and other media. Regular inspections guarantee high resistance to disinfecting agents, cleaners and other media used for cleanroom cleaning. nora® flooring is thus the perfect choice for planning and implementing modern cleanroom technology.

Individual solutions for every project

nora® rubber flooring can be used to realise a wide variety of projects and allow for optimal cleanroom cleaning processes. The nora® floor surfaces are available in a variety of thicknesses, structures and designs. This means that cleanrooms can be designed to optimise hygiene, quality assurance, safety, microbiology and facility management requirements.

We are happy to provide samples to planners and architects on request. We are also happy to suggest suitable cleanroom flooring that takes into account the specific requirements of the room in question. Thanks to years of experience around the world, we are able to provide active support to our customers as they decide on the right flooring surface solution for their cleanrooms.

Improve efficiency with uncoated floors

nora® rubber floors provide a dense, seamless surface with no need for seals or coatings. Maintenance remains efficient and cost-effective even in busy rooms requiring more frequent cleanroom cleaning. The cleanroom flooring is easy to maintain and care for even with frequent use. There is no need for costly restoration or resurfacing measures and the associated downtime they bring with them, making nora® rubber flooring the perfect choice for cleanrooms and other demanding areas of application.

10 year electrostatic properties warranty

ESD protection often plays an important role in cleanrooms. Static electricity can allow small particles to enter hygienic areas. But this is easily prevented using modern cleanroom technology and cleanroom flooring with optimal material properties for ESD protection.

nora® rubber flooring, capable of dissipating electrostatic charges, offers a reliable solution for ESD protected areas within cleanrooms. Its conductivity guarantees full surface dissipation without any additional coatings required, so there is no need to carry out costly resurfacing or deal with the associated downtime.

We offer a 10 year warranty on nora® rubber flooring’s electrostatic properties. But the flooring maintains its electrostatic characteristics above and beyond this period, providing a long-term, time-saving and cost-effective solution for cleanrooms.

Suited products*

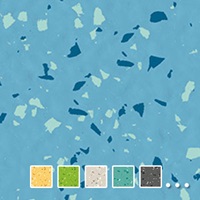

norament® 928 grano ed

Electrostatically dissipative “ed” floorings for optimum ESD protection of electronic devices and equipment. Protect against electrical shock, resist most oils and greases and are suitable for forklift truck areas.

noraplan® signa ed

Electrostatically dissipative “ed” floorings for optimum ESD protection of electronic devices and equipment. Protect against electrical shock, resist most oils and greases.

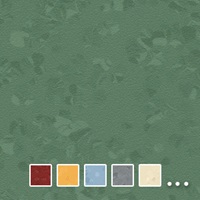

noraplan® sentica ed

Electrostatically dissipative “ed” floorings for optimum ESD protection of electronic devices and equipment. Protect against electrical shock, resist most oils and greases.

noraplan® astro ec

Electrostatically conductive “ec” floorings for optimum ESD protection of electronic devices and equipment.

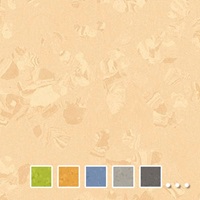

noracare™ seneo

For application areas with highest requirements for hygienic cleaning and maintenance as well as stain and chemical resistance. Single-coloured design with iridescent marbled colour granules, from a distance almost uni-coloured.

noracare™ uneo

For application areas with extraordinary demands on hygienic cleaning and maintenance as well as stain and chemical resistance. Single-coloured design with randomly scattered granite splinters, with a smooth surface.

Suitable for fast and safe installation: nora dryfix™ ed conductive dry adhesive.

* Please note: The floor coverings listed as "Suitable products" are not a final, fixed advice. We will be happy to recommend which floor covering is best suited to your individual situation. Please contact us.

Denmark | English

Denmark | English