nora® rubber floors provide the perfect combination of robust materials and long-term performance for maximum work safety. Our low-maintenance industrial flooring retains its high-quality appearance even after years of use. The extremely robust tiles for the factory floor create a surface that can reliably stand up to large loads, heavy blows and dirt.

Highly durable industrial flooring for the shop floor

Industrial flooring is subject to a great deal of stress. The mechanical stress is not limited to the many different people that walk across the floor daily: on the contrary, flooring for factories must be able to withstand extreme impacts, such as falling objects, heavy loads or pallets being dragged back and forth.

The industrial flooring norament® is perfectly tailored for use on the shop floor, thanks to a solid, incredibly durable surface. It provides a dense, seamless surface that can withstand even extreme impacts, with no need for additional surface treatments. No matter how busy the factory, our tiles for the factory floor maintain a well-kept look even after many years of use. The flooring does not need to be re-coated, keeping maintenance and upkeep costs to a minimum.

Made of homogeneous rubber, the natural elasticity makes our flooring ideal for industrial use. Rubber is the perfect material for flooring for factories, as it is resistant to impacts, for example from falling components, tools and heavy manufactured goods. At the same time, its shock-absorbing properties soften the blow. If necessary, the surface can be restored simply and at a low price point.

The right flooring for every shop floor

The seamless, extremely dense surface means that nora® rubber flooring is the ideal choice for hard-wearing industrial flooring. Many of our satisfied customers have been using nora® rubber flooring for decades, relying on its long-lasting, easy to maintain properties.

Depending on the type of subfloor, our industrial flooring can withstand a pressure load of up to 6 N/mm². We will be happy to calculate the dynamic pressure load for the intended area of use on request. We can then make a specific recommendation as to which flooring is optimally suited for the factory in question.

Robust, safe and low-maintenance

nora® rubber flooring reduces maintenance requirements to a minimum. However, should the flooring become damaged by protruding nails or sharp edges, partial replacement is a very simple process. The flooring for factories can also be repaired quickly and easily using nora®’s joint sealing compound.

Tiles on the factory floor are subject to abrasion and tyre marks from, for example, forklifts and other transports. These types of marks can be easily erased from nora® rubber flooring with help from nora® pads, keeping the floor looking spotless even after intensive use.

The nora floor supports our work in logistics

In 2001, norament grano was installed to Schleuniger in Thun, both in the logistics and in the ESD-protected production area. Even high pressure loads caused by daily driving of forklifts, lift trucks or other pallet trucks cannot affect the rubber floor. From mechanical loads to shear forces and pushing forces – norament grano withstands decades of work. It is excellently suited as an industrial floor and also offers a safe and easy-to-maintain solution in the long term. With the help of simple measures tire marks or other abrasion can be removed easily.

Suited Products

norament® grano™ ed

Electrostatically dissipative “ed” floorings for optimum ESD protection of electronic devices and equipment. Protect against electrical shock, resist most oils and greases and are suitable for forklift truck areas.

norament® xp™

norament® xp flooring goes beyond tough. Engineered for spaces that demand exceptional performance, it resists everything from heavy loads and harsh chemicals to extreme wear and tear.

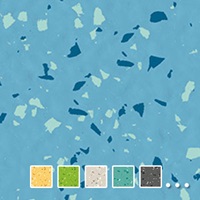

norament® grano™

Rubber flooring for extremely heavy traffic areas, with hammered surface and a granular design rich in contrast.

norament® satura™-

Vibrant collection available in saturated and neutral colors featuring a tone-on-tone granular design. Classic hammered surface or elegant slightly structured two-tone surface, both for use in very hight traffic areas.

Best fitting products

Detailed product recommendations by application area capturing all aspects of product variants at a glance

USA | English (US)

USA | English (US)